Ah, the good old capacity error. "Production order ***** could not be scheduled. Not enough capacity could be found."

There are a few main culprits for this error.

1. Calendar

The majority of the time, this error is caused by a Calendar issue. The most likely fix is that you are out of time, or almost out of time on your calendar and need to create new working times. This often happens near the end of the year, when the calendar is filling up and does not carry over to the next year.

2. Route

Your resources on your Route may be incorrect. I have seen some operations on a route that have been created to produce 1 item per 100 hours. It was an honest mistake and likely got flip-flopped during item creation. When the new item got scheduled, it blew out capacity and the order erred with the "Production order ***** could not be scheduled. Not enough capacity could be found." error.

|

| Oops! Someone put these values in backward! |

|

| Production order could not be scheduled. Not enough capacity could be found. |

3.Lead times

This one is a little more obscure. If you have an item with no routes specified, you can still receive this error! The error is likely coming from a lead time that has been set up on a component item on the BOM that has exceeded the Lead time in the Maximum job lead time field in the Production control parameters.

If this is set to zero or anything less than a lead time on a component item, you will get the "Production order could not be scheduled. Not enough capacity could be found."

|

| Maximum job lead time field can impact capacity and generate the capacity error! |

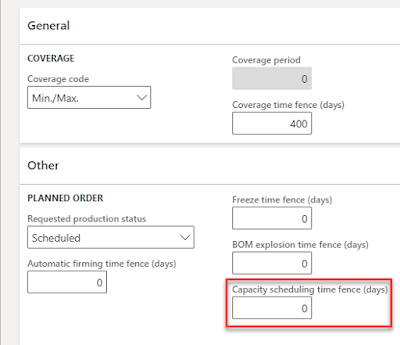

Likewise, you can set the Capacity scheduling time fence (days) on the Coverage group.

|

| Capacity scheduling time fence (days) field on the Coverage group |

Just ensure that the days you set are not exceeded by any lead times on any of your BOM component items, or this will trigger the "Production order could not be scheduled. Not enough capacity could be found." error.

No comments:

Post a Comment